Solutions / Problem areas

Contamination of products

Challenges

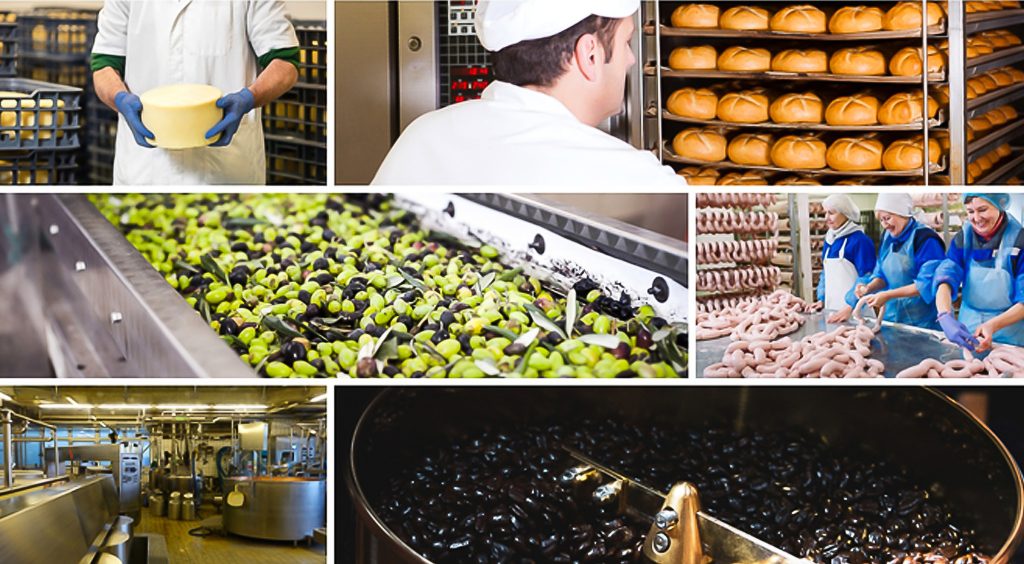

In all stages of product manufacturing, packing, and storing, indoor air quality is an important factor to consider when it comes to the technical cleanliness, quality, and shelf life of products. The indoor air at food and beverage production facilities, other production industries, logistics centers, and warehouses is often filled with particles from the various activities that take place in the premises. Particles from ingredients and components, mold spores, boxes, forklift tires, concrete, combustion, dirt, debris, and metal fragments, might all be polluting the air depending on your activity. And of course, all humans release a lot of particles too, 1.000.000 skin fragments per hour.

Solutions

To gain control over your indoor air quality, you need an air cleaning solution. We have freestanding air cleaners that can be placed on the floor or mounted on the ceiling, suitable for food and beverage production or other production facilities, as well as warehouses and logistics centers. We also have cleanroom solutions for extra sensitive production such as optics, electronics, MedTech or medicine production. With control over your air quality, you can ensure your products’ quality and life span. The integrity of your products will not only ensure your productivity and revenue, but it can also be a matter of health or even life and death for your customers, when you produce food or medicine.