Products / Air Cleaners

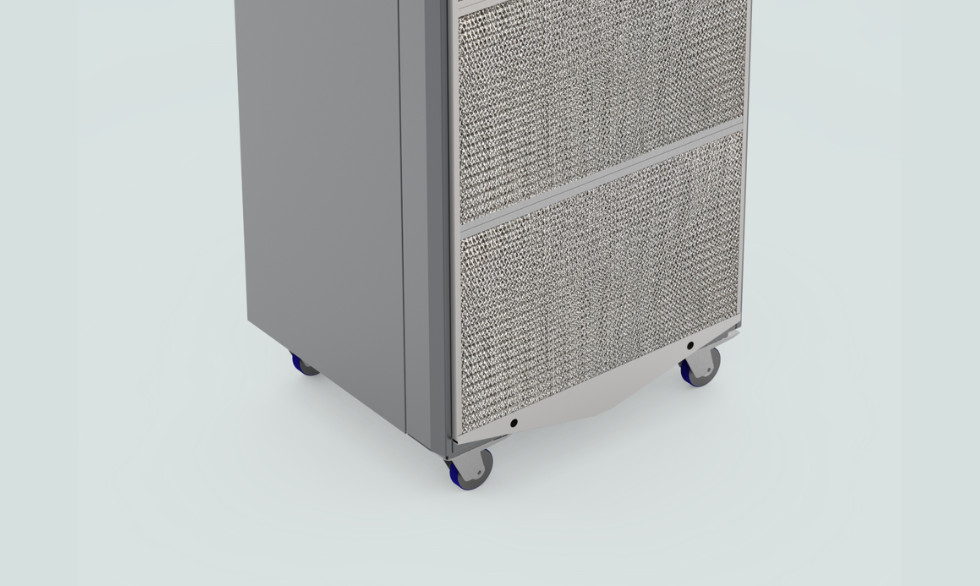

QleanAir FS 70 Oil Mist

An efficient air cleaner for solving an oil mist challenge

FS 70 Oil Mist is a powerful and energy efficient air cleaner developed to help industrial facilities facing challenges with oil mist and oil smoke to improve their indoor air quality. The unit is equipped with an oil mist metal mesh filter with a drainage function in combination with multi-stage mechanical filtration to separate oil mist as well as particles form the air. Thanks to its accessories such as air distribution tubing, vents, bends, and textile diffusers, FS 70 Oil Mist can be customized to meet the specific needs of your business.

Do you have questions about indoor air?

Welcome to contact us!

Key components of the FS 70 Oil Mist air cleaning solution

- Oil mist metal mesh filter with integrated drainage

- Multi-stage mechanical filtration classified according to ISO 16890

- Produces large volumes of air, up to 4000 m3/h

- Constant airflow regardless of filter saturation

- Filter alarm

- Quiet operation, <30–63 dB(A)

- Optional hoods, vents, ducts and diffusers

- Robust wheels for easy mobility

- Operates independently of heating, ventilation, and air-conditioning systems

- Scheduled service plan with filter replacement and upgrades

- Lifetime Performance Guarantee

This product can be delivered with QleanAir Connect, our new platform for connecting air cleaners and air quality sensors with a management system. Using a cloud solution, the quality of the air and functionality of the air cleaners can be monitored and controlled remotely. This allows for optimization and automatization of the air cleaners performance and real-time control over the air quality.

Benefits

FS 70 Oil Mist offers cleaner and safer indoor air. Cleaner air helps protect the health and safety of your employees. It also helps keeping the facility, products, machines, and inventory cleaner, and thereby ensuring product quality, reducing maintenance costs and safeguarding the life span of machinery.

FS 70 Oil Mist is versatile and can be customized to the specific needs of your facility, thanks to its available accessories. It uses an oil mist metal mesh filter with a drainage function in combination with a multi-stage mechanical filtration to separate oil mist as well as particles form the air. The unit´s constant airflow regulation in combination with preventive service package guarantee efficient air cleaning over time. The unit works independently of the ventilation system and uses the standard power socket, and it can easily be relocated if necessary thanks to it being equipped with wheels.

The technology behind the solution

The technology behind the solution

-

1. Air inlet

FS 70 Oil Mist has a large air inlet on the front of the unit to maximize intake volume and to reduce the risk of filter clogging.

-

2. Filtration of oil droplets and particles

Using an oil mist metal mesh filter in the front and a multi-stage mechanical filtration behind, airborne oil droplets and particles are effectively removed from the air.

-

3. Drainage channel

The filtrated oil is collected and drained from the filter for easy cleaning and disposal.

-

4. Cleaned air is returned to the environment

After the air is cleaned from airborne particles and contaminants, it is returned to the room by an adjustable outlet for optimal recirculation or diverted by optional tubes and diffusors to a specific area.

| Model | QleanAir FS 70 Oil Mist | ||

|---|---|---|---|

| Color | |||

| Dimensions (w x h x d) | 692 × 1527 × 615 mm | ||

| Dimensions on wheels | 692 × 1652 × 615 mm | ||

| Material | Powder coated sheet metal | ||

| Weight | 136 kg | ||

| Installation | Stationary, mobile or wall mounted | ||

| Performance levels | Seamless | ||

| Electronic display | Yes | ||

| Alarm functions | Filter full/Fan failure/Safety shutdown |

|

|

| Airflow | Up to 4000 m³/h* | ||

| Pre-filter | ePM1 60% (F7), Metal mesh filter | ||

| Main filter | ePM1 60% (F7) |

|

|

| Sound level | <30-63 dB(A) | ||

| Power supply | 200-240V, ~50-60 Hz, 3.3A | ||

| Energy consumption | 9-730W |

|

|

| Certifications and compliance |

|

||