How to reduce energy costs in your production facility – with freestanding air cleaners

Volatile energy prices as a result of global uncertainty and high inflation have had a major impact on many businesses. For manufacturing companies with high energy consumption, the impact is particularly significant.

Lowering the indoor temperature, turning off non-essential equipment or even limiting ventilation may certainly reduce costs in the short term, but can quickly lead to a deterioration in the working environment. Is it possible to reduce the energy costs without compromising on other aspects of the business?

Freestanding air cleaners can provide an energy-saving complement to production facilities without compromising on air quality and the working environment. Clean air also makes your equipment work better, last longer and require less maintenance. Product quality, longevity and technical cleanliness also depend on clean air.

In this article, we explain how free-standing air cleaners can help reduce your heating costs in large industrial premises.

Saving energy with freestanding air cleaners – how it works

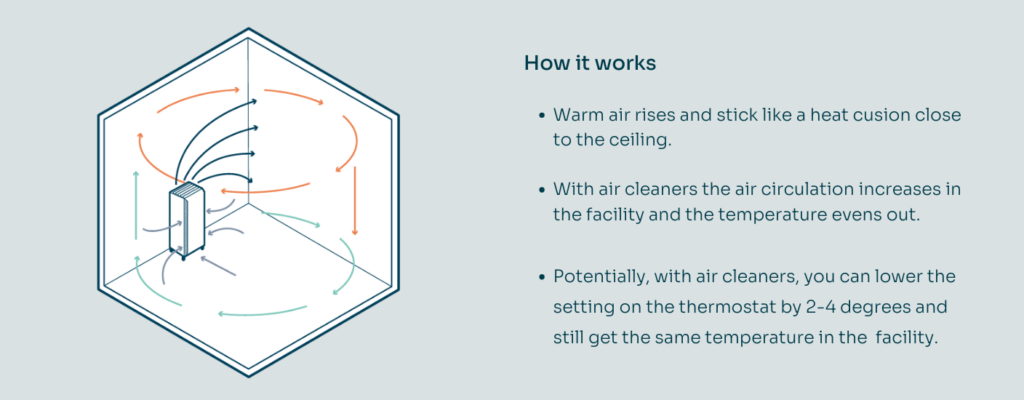

In large production facilities, robotic warehouses and premises with automated production lines, ceilings are usually high and the heated air tends to rise and stay there. A standard ventilation system is rarely powerful enough to circulate the air sufficiently, resulting in the heated air staying close to the ceiling like a heat cushion.

Freestanding air cleaners allow you to lower the temperature and still maintain a comfortable indoor climate. A major advantage of air cleaners is that they circulate the heated air, which in turn contributes to more even temperatures throughout the facility. At the same time, harmful particles are filtered out of the air, resulting in a better working environment and higher product quality and process efficiency.

CP Metal installed air cleaners, and the temperature rose 4-5 degrees.

QleanAir’s customer CP Metal A/S in Brædstrup, Denmark experienced this. It is a modern, order-producing forging workshop where all kinds of objects are welded, pressed and turned in aluminum, stainless and ordinary steel. When a QleanAir FS 70 stand-alone air cleaner was installed in the workshop, the temperature rose by 4-5 degrees almost immediately.

– The air cleaner is an indispensable tool for protecting workers from hazardous welding fumes. As a bonus, it reduces heating costs, says CEO Claus Kovdal Jørgensen.

Potentially, with air cleaners you can lower the thermostat setting by 2-4 degrees and still get the same temperature in the facility zone. The Swedish Energy Agency estimates that you can save 5% of heating costs per degree of temperature reduction.

How much energy does an air cleaner use?

But doesn’t installing additional products consume more energy? This is of course the case, but the fact is that they consume very little in the context.

For example, two of QleanAir’s air cleaners adapted for production facilities have an average power consumption equivalent to a household blender or a coffee maker, depending on the airflow:

- The QleanAir FS 70 has an average power consumption of 325 W, equivalent to a household blender, at an airflow of 3,000 m3/h.

- Our largest air cleaner, the QleanAir FS 90, consumes on average 800-900 W, equivalent to a standard coffee maker, but delivers an airflow of 6,500 m3/h.

Optimize air quality via the cloud

Our air cleaners can also be equipped with a cloud-based control system for monitoring the air cleaning solution. QleanAir Connect tracks key performance indicators such as airflow, energy consumption and air quality in real time and historically, allowing you to optimize airflow over time.

Energy saving tips for large production facilities

- Analyze the indoor air quality of your facility.

- Adapt ventilation to the level of activity in the space.

- Install air cleaners to clean and circulate the air.

- Lower the temperature. With air cleaners, you can potentially lower the temperature and still have a better and more even indoor climate.

- Choose a supplier with a full-service offering that guarantees the functionality of the air cleaners over time.

One step closer to clean air

QleanAir has over 30 years of experience in developing air cleaning solutions, including stand-alone air cleaners. Our customized solutions protect people, products and processes by meeting specific needs in production facilities.

We support you on the way to a healthier, safer and more productive working environment. Contact us for a free consultation.

Contact us

Read more about air cleaning solutions in the production industry

Read more about how air cleaning in production works and how it can contribute to a better working environment, cleaner products, less maintenance and more efficient processes:

Read more