How to choose the right air cleaning solution for your production environment

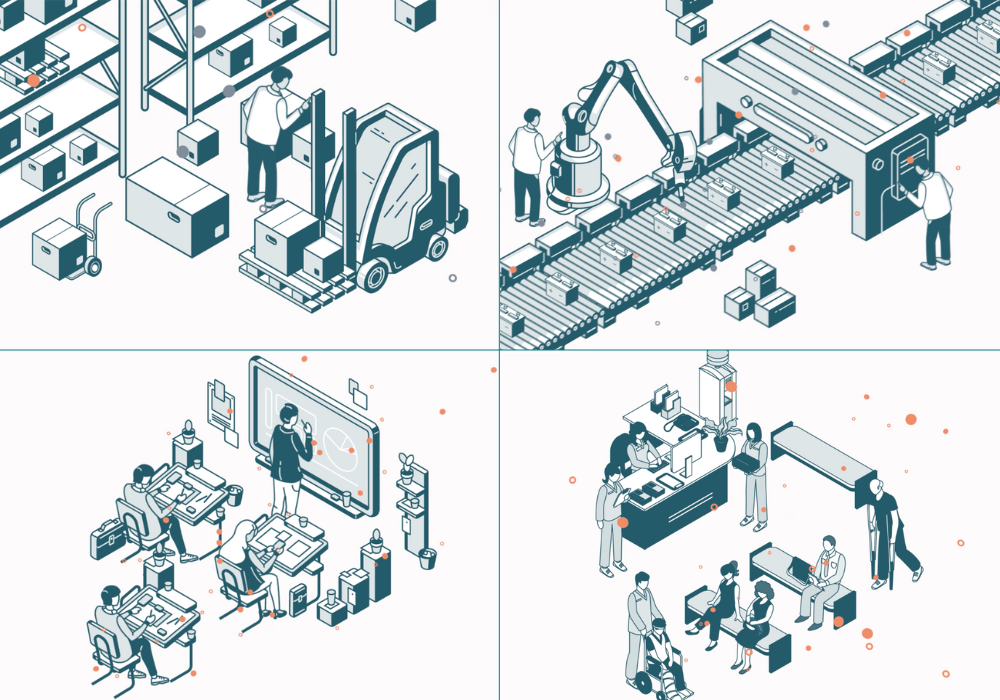

In the manufacturing industry, air quality is a key aspect of a healthy working environment and essential to ensure clean products, longer product life and more efficient processes. This is true whether you produce or process pharmaceuticals, plastic, metal or paper products.

Although both general and process ventilation are often installed in production facilities, these do not always solve challenges related to poor air quality or the presence of particles in the air. Often, a complementary air cleaning solution with stand-alone air cleaners may be needed. But how do you choose the right air cleaner for your production facility? What criteria should be evaluated?

1. What do you want to achieve with an air cleaning solution?

Choosing the right air cleaner for your production facility requires a strategy aimed at meeting specific challenges and achieving the desired results. It is therefore important to define what you want to achieve with an air cleaning solution – e.g. contribute to a healthier working environment, cleaner products, less downtime or reduced maintenance needs. However, investing in air cleaners often has several positive side effects in addition to addressing the challenge defined initially.

A common reason among manufacturing companies for wishing to improve their indoor air quality is for the sake of their employees and to create a healthier working environment. In many countries, checking and addressing the indoor air quality, is often part of the employers responsibility.

2. Define the problem

What air quality-related problems exist at the production facility? Initially, it is important to clearly define what the problem is. This can be done, for example, by investigating how the working environment is perceived and whether there are health issues related to air quality. Are there reports of allergic reactions, respiratory problems or other indications of pollutants in the air? And on that basis, is the problem related to cement dust, mold, hazardous gases, or perhaps odors?

Several airborne particles, such as cement dust, can contribute to workers developing serious health issues, such as asthma, lung infections, cardiovascular disease or even lung cancer. The Public Health Agency of Sweden stresses that, if employees experience bad air, odors or discomfort in the workplace, the quality of the air should be investigated.

In addition to the working environment, deviations and machine breakdowns in production processes may indicate that you have air quality problems, as well as product quality issues. Dust consists of a wide range of very small solid particles that can be generated from both processes and materials. It forms a layer on all kinds of surfaces, especially on machinery, which can lead to increased maintenance needs and machine failures as well as dirty products.

3. Define the sources of contamination

In order to choose the right air cleaning solution for your facility, it is necessary to analyze which processes or operations are the source of the particles or gases generated in the premises. Here, a particulate and a gas meter can be used to analyze which processes or activities generate the highest levels of contamination, and where an air cleaning solution can be most effective. Most often, the best option is to install an air cleaner close to the source of contamination, but there are different ways and applications depending on what is produced, the cleanliness requirements and what the production environment and associated ventilation systems look like.

4. Map out what the conditions in the production hall look like

The facility’s unique conditions play a major role in the design and sizing of an air cleaning solution. The size of the premises, their design and layout, the existing ventilation system and any process ventilation and how this is adapted to the premises and, above all, what specific production processes and other activities are performed. There is an interplay of factors that influence which air cleaner and air filter are suitable for the unique production environment, as well the optimal number and positioning of air cleaners.

5. Evaluate different options

Once you have identified the above points, you have come a long way. You probably know what type of air cleaner you need, how many units are required for the premises in question, which filter configuration is needed for the pollutants you have a problem with, etc.

In addition, there are a number of parameters to take into account. Here, we list a few that are good to keep in mind.

-

Technical conditions

Evaluate the technology used to ensure that the airflow is maintained over time and that the air cleaner does not use technology that releases harmful particles or gases. It can also be valuable to look at the filter configuration to determine how much particle removal it delivers, as well as whether the air cleaner has a function to indicate when filter replacement is necessary, whether it can be controlled remotely to, for example, adjust for optimal daily operation or other monitoring.

-

Certifications and compliance

Choose a third-party certified air cleaner to ensure it meets basic requirements, but also to get an idea of its performance, efficiency, energy consumption and compliance with specific requirements that are important to your business.

-

Size and noise level

An air cleaner should not be larger than the needs of the facility. In other words, consider how much space it takes up in relation to the amount of air cleaning capacity you need. Also consider the noise level for the sake of the working environment.

-

Service, warranty and installation

Air cleaners require regular maintenance and filter changes to maintain optimal performance over time. Think about your need for help with installation, service and maintenance and warranties. Regular monitoring of air quality, filter status and filter changes is important to minimize downtime and ensure a constant air cleaning capacity.

Which air cleaner should you choose?

The most suitable air cleaner for your business depends on your needs, i.e. the type of particles or gases present in your premises, the size of the premises and the activities carried out there, etc. Do your research and consult an expert before making a decision.

One step closer to clean air

QleanAir develops free-standing air cleaners that, with the help of different filter configurations, can be adapted to each unique need, depending on the environment. All our air cleaners use multi-stage mechanical filtration to capture air pollutants and particles of different sizes. In addition, the air cleaners are equipped with automatic flow control to ensure the same airflow over time regardless of filter saturation, helping to maintain optimal air quality in the room.

Depending on your needs, we deliver clean air as a service, with hassle-free installation, ongoing maintenance, upgrades and filter changes. Our unique Lifetime Performance Guarantee, guarantees that our air cleaners work over time.

Contact us

We are happy to support you on the journey toward a healthy, safe and productive work environment. Welcome to contact us for a free consultation.

Contact us